Dishwashers, laundry

- Home

- Dishwashers, laundry

- Dishwashers

- Dishwashers

- Belt-towing ware-washer, 1,147 / 1,877 mt/m'

Belt-towing ware-washer, 1,147 / 1,877 mt/m'

| Model | LP4000-DY |

| Power Type | Electrical |

| Power | 72.65 kW |

| Dimensions | 6300x1210x2025 mm |

| Weight | 1260 kg |

| Water Inlet | ¾” |

| Water Outlet | 1“½ |

| Voltage | 400 V/3/50 Hz |

| Producer | Lamber |

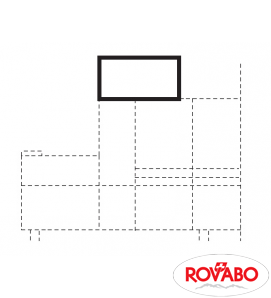

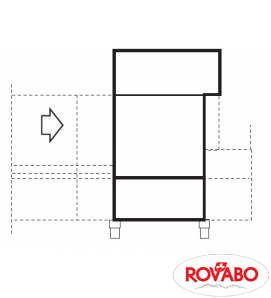

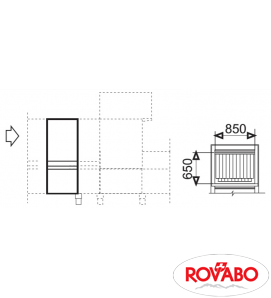

Body and tank stainless steel construction 18/10 AISI 304, 12/10 thick. Solid, high temperatures resistant, non-deformable belt conveyor 625 mm width (for LINEAR-ek-L 850 mm possible) with stainless steel chain and roll in nylon for a silent sliding. Tunnel composition: 1 pre-wash (230 l) - wash arms: 6 upper + 4 lower + 2 side arms, 1 wash (230 l) - wash arms: 6 upper + 4 lower + 2 side arms, 1 rinse (550 l) - rinse arms: 1 upper + 1 lower. Completely automatic. S.S. pre-wash (40°С), wash (60°C) and rinse (85÷90°C) arms with studs molded towards the outside allowing to increase the opening width of the washing jet, and also allowing the washing arms to be completely emptied of any unwanted residues, easy to disassemble and change. The new concept WASHING ARMS WITH BALANCED JET allow to uniformly distribute the pressure of water on the dishes, ensuring therefore effective washing results. Double skin with thermic and acoustic insulation. Insulated drawing washing tanks with rounded edges; guarantee the highest hygiene. Stainless steel self-draining inclined washing pumps. The drain valve allows to automatically empty the tanks. The washing flow regulator allows to gauge the washing strength intensity (useful for glasses washing), placed inside the pre-washing and washing zones by the lower washing arms. WRS system: recovery rinse water in pre-washing. Counterbalanced door. Inspection door, placed at the entry and at the exit, for easy access to the below tanks for cleaning. New electronic touch control panel, with two separate displays, dedicated to temperature management only! Types of management: for the operator, for the maintenance, and for technician and factory data. The interactive display allows you to view the temperatures and program all the values to be set for all the functions available. Autotimer allows to reduce water and energy consumption. Frontal maintenance. Water protection. Loading modular bracket with table for dishes bearing. Automatic tank loading. Start and stop button in entry-exit machine. Rinse economizer (the photocell on entry table therefor blocks the leak of hot rinse water if on the belt there are no dishes). Tank and pump filters. Insulated Boiler. Safety. Adjustable and strong feet. Flowmeter. Emergency pushbutton in entrance and exit of the machine. Pressure switch protection for heating elements. Thermic protection for wash pump. Automatic stopping of conveyor in case of foreign bodies. Low voltage control circuit (24V) for greater safety during work operation. Dishes (stop with end micro-switch on the exit table). Door opening safety device. Emergency lamp. Energy regeneration with heat pump with simple, double and triple action exploiting the heat produced in the cooling cycle, which allows to constantly regenerate energy from the hot air produced in the machine. Technical specifications. Two automatic speeds: 1st - 1,147 mt/m', 2nd - 1,877 mt/m'. Max dimensions for wash: 650 mm height - 850 mm width. Cycle water consumption: 320 l/h. Hardness: 5-10°F. Noise: dB 69. Options: drying tunnel; steam condenser; pressure pump; extension table (entry-exit); heat recoverer; heat pump; removable front drawer for PRL-CN pre-washing unit, with two 50 mm deep inox filters (mesh ø3 mm). Cold water connection upon request.

Accessories